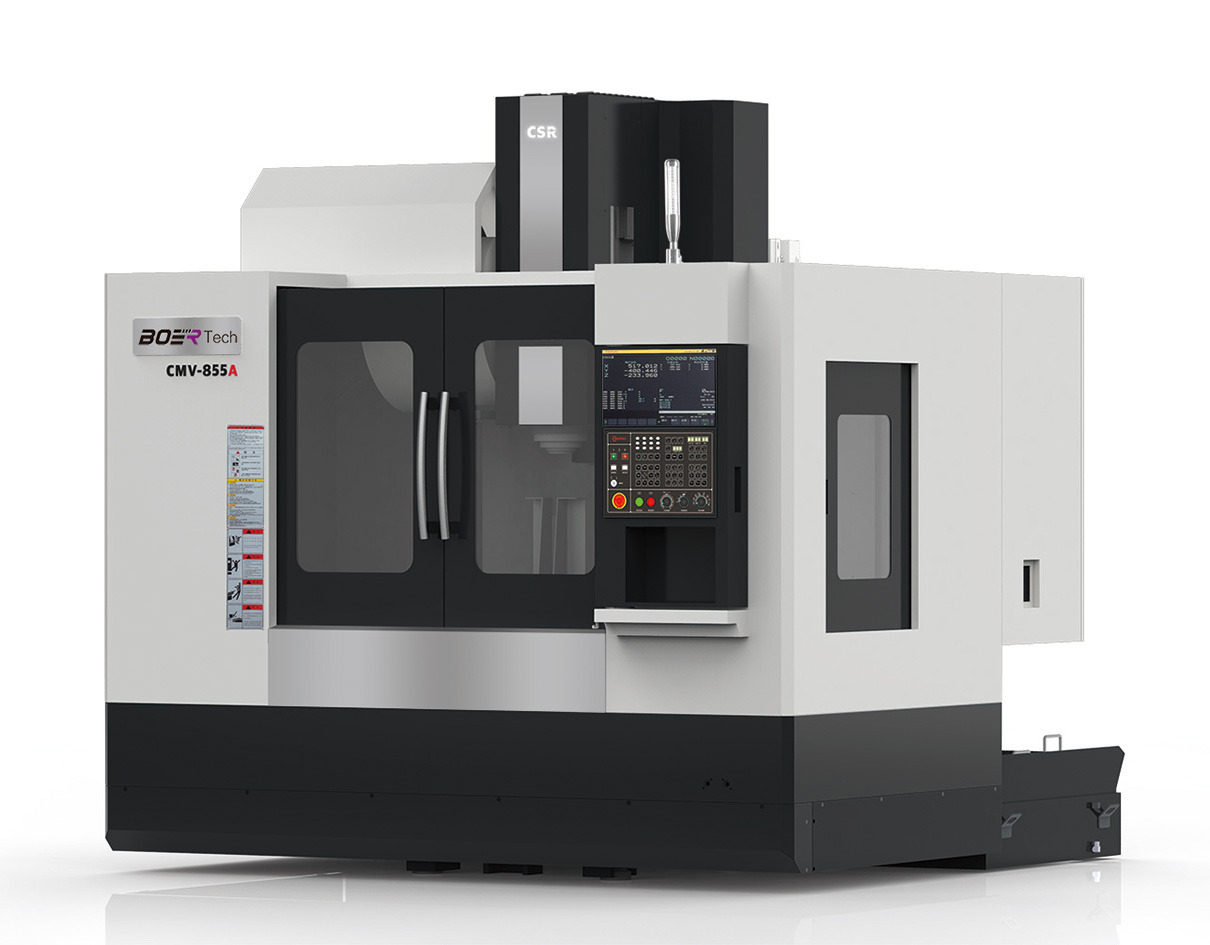

CMV855A

CMV855A

High rigidity structural design: The ultra wide base and body casting design ensure that the machine can achieve better support and cutting rigidity during high-speed operation; Strong and high-quality Mihanna cast iron provides superior damping effect and perfect machining accuracy.

High precision axial feed design: using precision linear sliding rails to improve machine speed and stability; The precision ball screw is driven by a direct connection motor, providing high torque and reducing backlash.

Reinforced casting of structural components: The mechanical castings are made of high-grade mihanna cast iron, which reduces twisting deformation and improves shock absorption capacity; The cast embryo undergoes secondary tempering and aging treatment. Conduct a comprehensive inspection before and after processing to ensure perfection and flawlessness.

Excellent shock-absorbing performance: Through the application of materials science, MiHanna cast iron significantly improves the shock-absorbing performance of the spindle box. Combined with the box shaped column structure, it naturally forms a solid and stable processing platform that is integrated with the bed.

High precision axial feed design: using precision linear sliding rails to improve machine speed and stability; The precision ball screw is driven by a direct connection motor, providing high torque and reducing backlash.

Reinforced casting of structural components: The mechanical castings are made of high-grade mihanna cast iron, which reduces twisting deformation and improves shock absorption capacity; The cast embryo undergoes secondary tempering and aging treatment. Conduct a comprehensive inspection before and after processing to ensure perfection and flawlessness.

Excellent shock-absorbing performance: Through the application of materials science, MiHanna cast iron significantly improves the shock-absorbing performance of the spindle box. Combined with the box shaped column structure, it naturally forms a solid and stable processing platform that is integrated with the bed.

| Model | UNIT | TV-600 | TV-700 | DV-850 | CMV-855 | CMV-1160A | CMV-1167A | CMV-1265A | CMV-1380 | CFV-1380A | CFV-1580A | CML-855A | CML-1160A | CFL-1270A | CFL-1370A | CFL-1580A | CFL-1690A | CFL-1890A |

| Stroke | ||||||||||||||||||

| X-axis | mm | 600 | 700 | 800 | 800 | 1100 | 1100 | 1200 | 1300 | 1300 | 1500 | 800 | 1100 | 1200 | 1300 | 1500 | 1600 | 1800 |

| Y-axis | mm | 440 | 400 | 500 | 550 | 600 | 650 | 650 | 800 | 800 | 800 | 550 | 600 | 700 | 700 | 800 | 900 | 900 |

| Z-axis | mm | 330 | 330 | 500 | 550 | 600 | 750 | 650 | 700 | 700 | 700 | 550 | 600 | 600 | 650 | 700 | 680 | 680 |

| Spindle nose to workable | mm | 140-470 | 140-470 | 150-650 | 120-670 | 120-720 | 95-845 | 120-770 | 150-850 | 160-860[Note3] | 160-860[Note3] | 120-670 | 180-780 | 87-687 | 150-800 | 185-885 | 160-840 | 160-840 |

| Worktable | ||||||||||||||||||

| Table size | mm2 | 700*420 | 800*420 | 1000*500 | 1000*500 | 1200*600 | 1200X650 | 1300X650 | 1400X800 | 1400X800 | 1600X800 | 1000X550 | 1300X600 | 1360X700 | 1400X700 | 1700X800 | 1800X900 | 2000X900 |

| Load(Max.) | kg | 250 | 350 | 400 | 500 | 800 | 800 | 600 | 1200 | 1300 | 1500 | 500 | 800 | 1000 | 1000 | 1500 | 1600 | 1600 |

| T-slot(QTY.-Width×Distance) | 3-14*125 | 3-14*125 | 5-18*90 | 5-18*90 | 5-18*100 | 5-18X120 | 5-18*120 | 7-18*110 | 7-18*110 | 7-22X110 | 5-18X90 | 5-18X120 | 5-18X122 | 5-18X152 | 5-22X135 | 5-22X165 | 5-22X165 | |

| Feedrate | ||||||||||||||||||

| Rapids on X/Y/Z axis | m/min | 48/48/48 | 48/48/48 | 48/48/36 | 36/36/36 | 36/36/36 | 36/36/36 | 30/30/30 | 30/30/30 | 30/30/30 | 24/24/24 | 24/24/18 | 24/24/18 | 20/20/15 | 20/20/15 | 18/18/15 | 18/18/15 | 18/18/15 |

| Cutting Feedrate | mm/min | 1~10000 | 1~10000 | 1~10000 | 1~10000 | 1~10000 | 1~10000 | 1~10000 | 1~10000 | 1~10000 | 1~10000 | 1~10000 | 1~10000 | 1~10000 | 1~10000 | 1~10000 | 1~10000 | 1~10000 |

| Spindle | ||||||||||||||||||

| Speed | rpm | 20000 | 20000 | 12000 | 10000 | 10000 | 10000 | 10000 | 8000(Optional ZF Reduction) | 10000 | 10000 | 8000(Optional BT40) | ||||||

| Drive type | D-D | D-D | 直接式(Optional Synchronous Belt) | Synchronous Belt | Synchronous Belt | Synchronous Belt | Synchronous Belt | Synchronous Belt | Synchronous Belt | Synchronous Belt | Synchronous Belt | Synchronous Belt | Synchronous Belt | Synchronous Belt | Synchronous Belt | Synchronous Belt | ||

| Taper | #ISO | BT30 | BT30 | BT40(Optional BBT40、HSK A63) | BT50 | BT50(Optional BT40) | BT40 | BT40 | BT50 | BT50 | BT50 | BT50 | BT50 | |||||

| Motor Power | kw | 3.7/5.5 | 3.7/5.5 | 11/15 | 11/15 | 11/15 | 11/15 | 11/15 | 11/15 | 15/18.5 | 15/18.5 | 11/15 | 11/15 | 15/18.5 | 15/18.5 | 15/18.5 | 15/18.5 | 15/18.5 |

| ATC | ||||||||||||||||||

| Capacity | 21 | 21 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | |

| Max tool diameter(full)/(no adjacent tools) | mm | 80 | 80 | 78/120 | 78/120 | 78/120 | 78/120 | 78/120 | 78/120 | 105/200 | 105/200 | 78/120 | 78/120 | 105/200 | 105/200 | 105/200 | 105/200 | 105/200 |

| Max. Tool Length | mm | 200 | 200 | 300 | 300 | 300 | 300 | 300 | 300 | 350 | 350 | 300 | 300 | 350 | 350 | 350 | 350 | 350 |

| Max. Tool Weight | kg | 3 | 3 | 8 | 8 | 8 | 8 | 8 | 8 | 15 | 15 | 8 | 8 | 15 | 15 | 15 | 15 | 15 |

| Tension bolt | MAS403P30T-1 (45°) | MAS403P40T-1 (45°) | MAS403P50T-1 (45°) | MAS403P40T-1 (45°) | MAS403P50T-1 (45°) | |||||||||||||

| Machine Accuracy [Laser measurement] Environmental requirement:Within 12 hours before the test,The ambient temperature change of the machine shall not be more than 4℃.The temperature changed of the environment shall not more than 2℃ when the machine on testing. | ||||||||||||||||||

| Three-axis laser positioning(JISB 6338Field measurement method/Check Note1) | ||||||||||||||||||

| Accuracy (Full Stroke) | mm | ±0.005 | ±0.005 | ±0.005 | ±0.005 | ±0.005 | ±0.005 | ±0.005 | ±0.005 | ±0.005 | ±0.006 | ±0.005 | ±0.005 | ±0.005 | ±0.005 | ±0.006 | ±0.006 | ±0.006 |

| Repeatability (Full Stroke) | mm | ±0.003 | ±0.003 | ±0.003 | ±0.003 | ±0.003 | ±0.003 | ±0.003 | ±0.003 | ±0.003 | ±0.004 | ±0.003 | ±0.003 | ±0.003 | ±0.003 | ±0.004 | ±0.004 | ±0.004 |

| Three-axis laser positioning(VDI/DGQ 3441Statistical method/Check Note2) | ||||||||||||||||||

| Accuracy(P) (Full Stroke) | mm | 0.008 | 0.008 | 0.008 | 0.008 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.012 | 0.008 | 0.008 | 0.01 | 0.01 | 0.012 | 0.015 | 0.015 |

| Repeatability Ps max.(Full Stroke)) | mm | 0.005 | 0.005 | 0.005 | 0.005 | 0.006 | 0.006 | 0.006 | 0.006 | 0.006 | 0.006 | 0.005 | 0.005 | 0.006 | 0.006 | 0.006 | 0.007 | 0.007 |

| Oil-gas pressure system | ||||||||||||||||||

| Capacity of cutting fluid | L | 250 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 400 | 300 | 300 | 300 | 300 | 400 | 400 | 400 | |

| Capacity of Lubricating oil tank | L | 3 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 6 | 4 | 4 | 4 | 4 | 6 | 6 | 6 | |

| Air Pressure Requirement(MIN) | kg/cm2 | 6 | ||||||||||||||||

| Others | ||||||||||||||||||

| Power Required | Vac | (220±10%) | ||||||||||||||||

| KVA | 15 | 15 | 20 | 25 | 25 | 25 | 25 | 30 | 30 | 40 | 20 | 25 | 25 | 30 | 40 | 40 | 40 | |

| Voltage | phase | 3 | ||||||||||||||||

| Hz | 50/60 | |||||||||||||||||

| Machine Weight(Rough) | kg | 2700 | 2900 | 5000 | 5200 | 6300 | 6500 | 7000 | 8000 | 9500 | 9800 | 5600 | 7800 | 9000 | 11000 | 13000 | 13800 | 14600 |

| Note1:JISB6338The standard deviation is not calculated in the measured method. And the actual measured value shall prevail. Note2:VDI3441Statistical method calculated 6 standard deviations. With 99.73% quality assurance. Note3:Optional BT40(∅150)-8000/12000:190-890mm、BT50(∅155)-8000:160-860mm、BT50(∅190)-6000:185-885mm。 Note4:Company reserves the right to change the content and text of the record at any time due to technical requirements. | ||||||||||||||||||