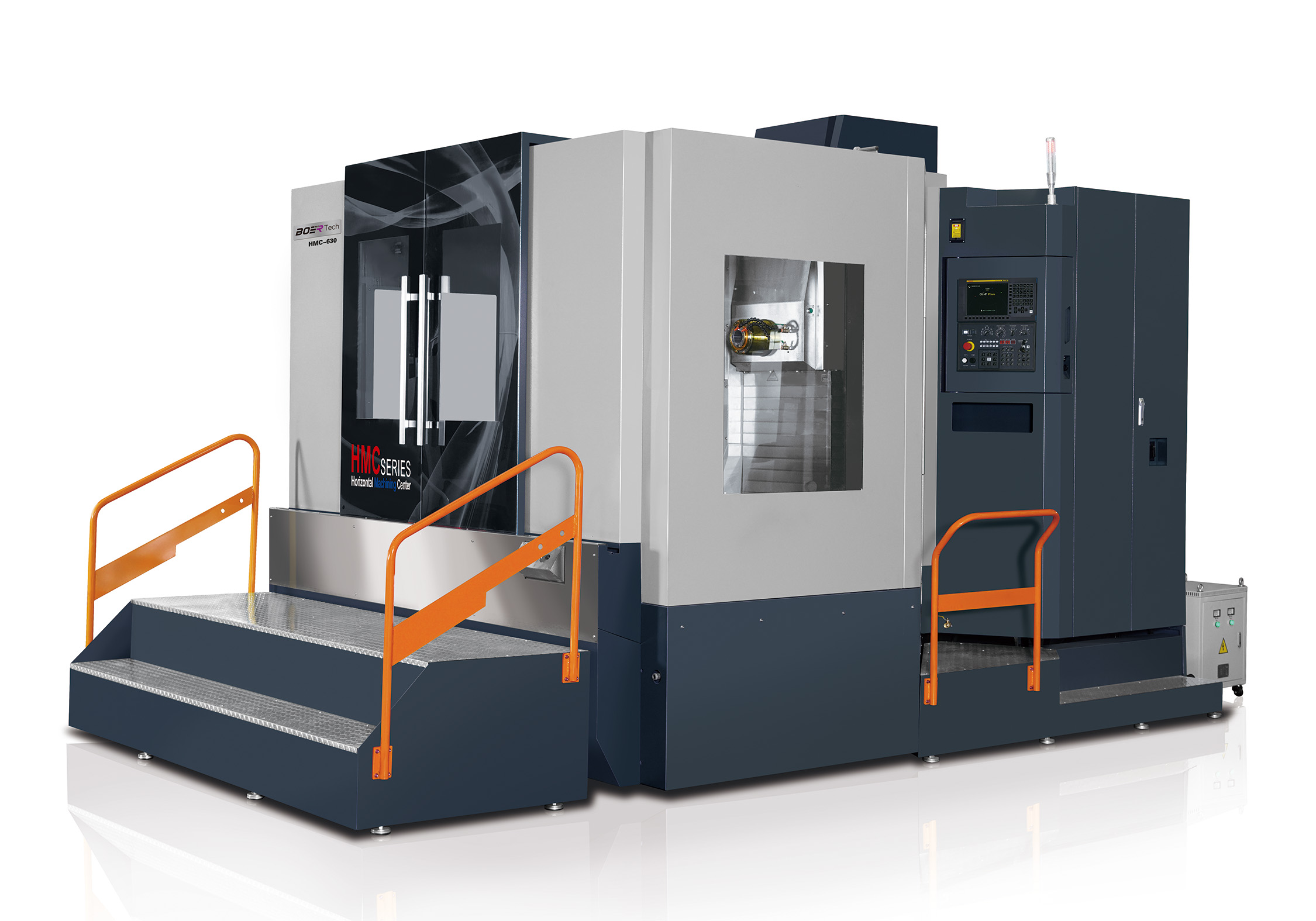

HMC630

HMC630

Applicable industries:

Automotive, aerospace, electronics industry, various types of box and shell parts processing.

High efficiency horizontal machining center:

The base adopts an inverted "T" layout, and through finite element analysis, the casting rib layout structure is optimized to improve overall performance indicators. The entire stroke does not produce overturning torque, and a high-precision spindle is used with a standard speed of 6000rpm, equipped with spindle air curtain protection, stable accuracy and long service life. The spindle adopts a high-power constant torque motor with a high rigidity roller guide rail structure, which combines the rigid re cutting of hard rails and the fast moving characteristics of linear guides. The precision turntable has ultra-high positioning and repeated positioning accuracy, ensuring the machining accuracy of the workpiece.

Automotive, aerospace, electronics industry, various types of box and shell parts processing.

High efficiency horizontal machining center:

The base adopts an inverted "T" layout, and through finite element analysis, the casting rib layout structure is optimized to improve overall performance indicators. The entire stroke does not produce overturning torque, and a high-precision spindle is used with a standard speed of 6000rpm, equipped with spindle air curtain protection, stable accuracy and long service life. The spindle adopts a high-power constant torque motor with a high rigidity roller guide rail structure, which combines the rigid re cutting of hard rails and the fast moving characteristics of linear guides. The precision turntable has ultra-high positioning and repeated positioning accuracy, ensuring the machining accuracy of the workpiece.

| Model | UNIT | HMC-500 | HMC-630 | HMC-800 | HMC-1000 |

| Stroke | |||||

| X-axis | mm | 700 | 1050 | 1400 | 1600 |

| Y-axis | mm | 625 | 750 | 1100 | 1100 |

| Z-axis | mm | 650 | 900 | 1100 | 1100 |

| Spindle center to worktable | mm | 100-725 | 120-780 | 130-1230 | 130-1230 |

| Spindle nose to worktable | mm | 70-720 | 130-1030 | 200-1300 | 200-1300 |

| Worktable | |||||

| Table size | mm2 | 500x500 | 630x630 | 800x800 | 1000x1000 |

| Swing over bed(Max.) | mm | Ø600 | Ø1100 | Ø1600 | Ø1600 |

| B-axis indexing (continuous indexing) | 1°×360 | ||||

| Load(Max.) | kg | 600 | 1200 | 1800 | 3000 |

| Feedrate | |||||

| Rapids on X/Y/Z axis | m/min | 24/24/24/10 | 10/10/10/3 | ||

| Cutting Feedrate | mm/min | 1-10000 | 1-10000 | 1-10000 | 1-10000 |

| Spindle | |||||

| Speed | rpm | 8000 | 6000 | ||

| Drive type | Synchronous Belt | ||||

| Taper | #ISO | BT40 | BT50 | ||

| Motor Power | kw | 15-18.5 | 15-18.5 | 15-18.5 | 15-18.5 |

| ATC | |||||

| Capacity | 30(Optional 40) | ||||

| Max tool diameter(full) | mm | Ø110 | |||

| Max tool diameter(no adjacent tools) | mm | Ø200 | |||

| Max. Tool Length | mm | 350 | |||

| Max. Tool Weight | kg | 18 | |||

| Type | Arm type | ||||

| Machine Accuracy [Laser measurement] Environmental requirement:Within 12 hours before the test,The ambient temperature change of the machine shall not be more than 4℃.The temperature changed of the environment shall not more than 2℃ when the machine on testing. | |||||

| Three-axis laser positioning(JISB 6338Field measurement method/Check Note1) | |||||

| Positioning Accuracy(Full Stroke) | mm | ±0.005 | ±0.006 | ||

| Repositioning Accuracy(Full Stroke) | mm | ±0.003 | ±0.004 | ||

| Three-axis laser positioning(VDI/DGQ 3441Statistical method/Check Note2) | |||||

| Accuracy(P) (Full Stroke) | mm | 0.012 | 0.016 | ||

| Repeatability Ps max.(Full Stroke)) | mm | 0.008 | 0.01 | ||

| Oil-gas pressure system | |||||

| Capacity of cutting fluid | L | 300 | |||

| Capacity of Lubricating oil tank | L | 6 | |||

| Air Pressure Requirement(MIN) | kg/cm2 | 6 | |||

| Others | |||||

| Power Required | Vac | (220±10%) | |||

| KVA | 40 | 60 | |||

| phase | 3 | ||||

| Hz | 50/60 | ||||

| Machine Weight(Rough) | kg | 9500 | 13000 | 16500 | 19500 |

| Note1:JISB6338The standard deviation is not calculated in the measured method. And the actual measured value shall prevail. Note2:VDI3441Statistical method calculated 6 standard deviations. With 99.73% quality assurance. Note3:Company reserves the right to change the content and text of the record at any time due to technical requirements. | |||||